BuBclean is working on improving the ultrasonic equipment in the NanoLab facilities of the MESA+ Institute for Nanotechnology (University of Twente). The processing of wafers is sometimes insufficient or inconsistent, and insight into the cause of this inconsistency is wanted.

BuBclean is working on improving the ultrasonic equipment in the NanoLab facilities of the MESA+ Institute for Nanotechnology (University of Twente). The processing of wafers is sometimes insufficient or inconsistent, and insight into the cause of this inconsistency is wanted.

The goal of the work activities is to characterise and improve the ultrasonic processing of semiconductor wafers. Using characterisation measurements, such as shown below, we can check the proper functioning of the ultrasonic baths, the optimal positions inside the bath, and the influence of the containers on the cavitation.

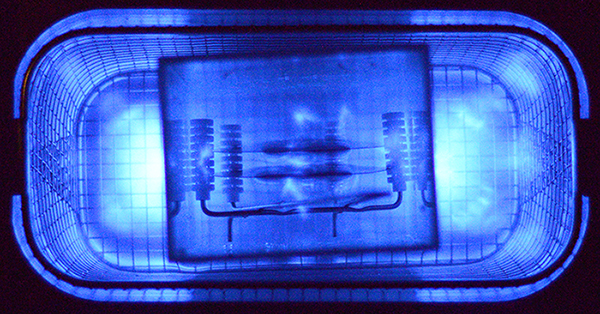

Top view of an ultrasonic bath with container and two wafers. The blue color represents cavitation.

Top view of an ultrasonic bath with container and two wafers. The blue color represents cavitation.for wafers under different circumstances (containers, chemicals, etc.).

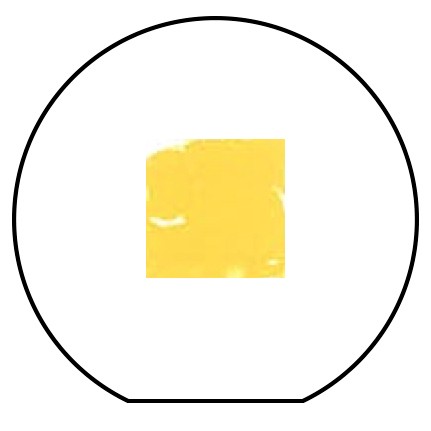

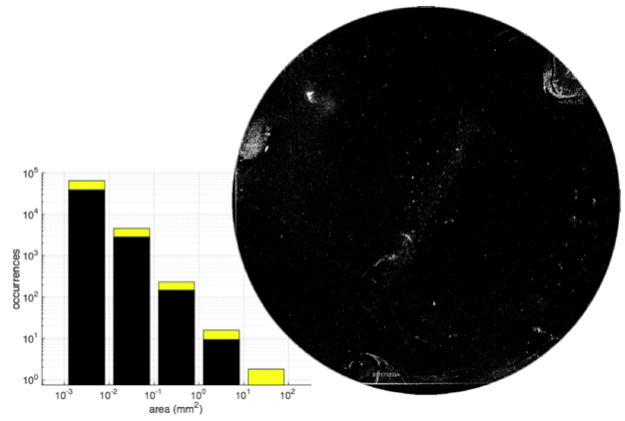

The wafers may contain nanoscale structures and have to be free of organic and metallic contamination, such as in metal lift-off processes and after Chemo-Mechanical Polishing (CMP) or dicing/cleaving of wafers. For the latter process, we have done extensive measurements on the ultrasonic removal of silicon particles, measured with a particle counter.

Measurement results from a particle counter after manually contaminating a 4″ wafer with silicon particles. Particle analysis, counting and sorting into 5 size categories has been automated. The effectivity of the cleaning can be quantified by making another scan of the same wafer after a cleaning step.

The measurements have resulted in several advises to implement a functional and usable ultrasonic cleaning setup, with which good, fast and reproducible cleaning of wafers can be achieved, and hopefully cross-contamination is reduced as well. Protocols for the cleanroom users have been made available, and they will be informed during a colloquium session.

This project was financially supported by the Province of Overijssel.