Our BuBble bags are a new, innovative type of container for use in ultrasonic baths. The insides of the bag have been modified with a specific pattern in order to promote cleaning. This patented modification generates a lot more microbubbles, which leads to better and faster cleaning of objects inside the BuBble bag.

1-minute explanation:

ADVANTAGES

- Faster and better ultrasonic cleaning

- No cross-contamination between cleaning jobs or users

- Less cleaning liquid necessary

- Multiple cleaning liquids can be used simultaneously

- The ultrasonic bath remains clean

- Prolonged life of the ultrasonic bath

- No contact damage when cleaning multiple items

- Parts that are detached during cleaning are not lost

SPECIFICATIONS

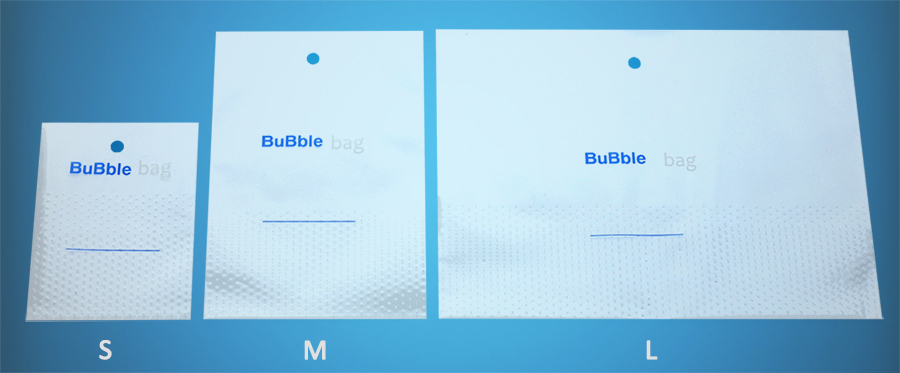

| Size | ‘Small’ – 75×100 mm (20 mL) |

| ‘Medium’ – 100×150 mm (50 mL) | |

| ‘Large’ – 200×150 mm (100 mL) | |

| Choose the size that fits best your objects and the depth of your ultrasonic bath. | |

| Other sizes are possible on request. | |

| Material | 50µm thick (recycled) PP |

| Resistant to most commonly used cleaning liquids and doesn’t block the ultrasound (as compared to the commonly used glass beakers, metal baskets and plastic cups). | |

| Recycle through the plastic disposal. | |

| Filling mark | Indicates the optimal filling level. |

| Punch hole | For mounting of the bag inside an ultrasonic bath (see also the accessories). |

| Closing | Close the bag water-tight using our clips |

| Packaging | Per 150 (S), 100 (M) or 50 (L) bags in a specially designed dispenser box. |

Photo of the three available BuBble bags formats.

TIP: Hover over the image to reveal the dimensions

APPLICATIONS

Click on the links below to read detailed examples of how BuBble bags can enhance specific cleaning applications.

Multi-user labs for research. Cleaning of microscope glass, tweezer, objectives, lab-on-a-chip, etc., without cross-contamination between users.

Also for emulsifying, particle synthesis, graphite exfoliation, radical generation (sonochemistry), salt dissolution, etc.

DENTISTS

Cleaning of files, mirrors, pliers, etc. No contact damage to diamant burrs; no cross-contamination.

HIGH-TECH

Screws, ferrules, 3D printed parts, etc. cleaned of dust and lubricants. Also useful for microfluidic chips. No cross-contamination between wafers in cleanrooms.

METAL INDUSTRY

Cleaning after machining, also for precision technology and miniature parts.

>> For more ideas, visit our blog.